Engineer Technology

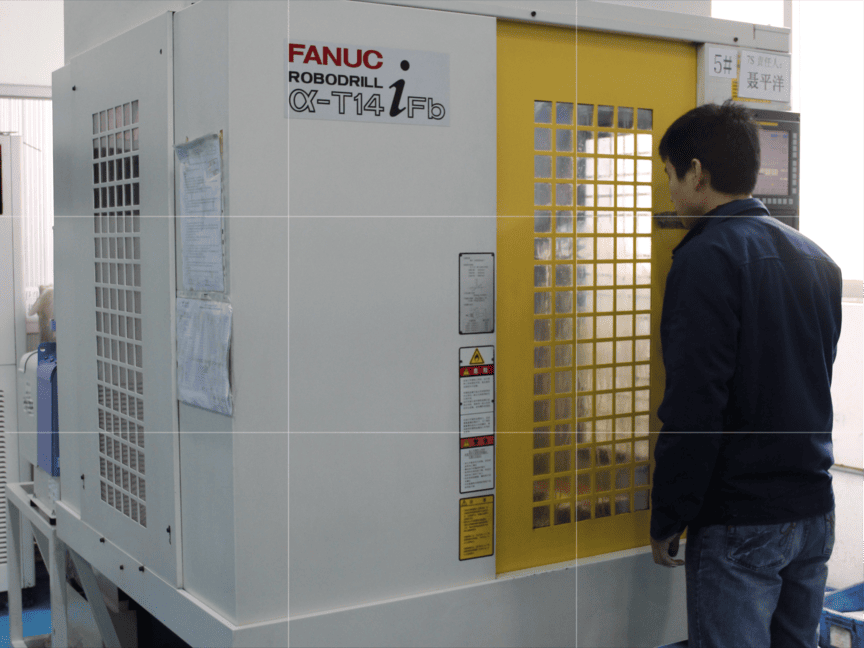

ATC-Mould starts from the source of the mold and purchases imported high-quality steel materials, LKM, HASCO DMED and other standard mold embryos. It has imported CNC, WIRE CUT, EDM equipment. The processing accuracy of the machine is +/-0.005 mm. It has advanced three-dimensional testing equipment to realize interchangeable parts processing and reduce the assembly time of later molds. It has 50-2000 tons of injection molding machines to provide customers with high-quality plastic products

cavity & core rough machining include

Drilling machine (drilling water transportation holes, empty avoidance holes, ejector pin holes above ± 10, threading holes above ± 4, etc.)

Milling machine (machining throat teeth, screw holes, chamfers, etc.)

CNC rough machining (parting line, line slots, insert holes, etc.)

In order to meet the high life requirements of the mold, we will heat treat the pre-hardened steel to improve the hardness and wear resistance of the steel. In order to reduce the risk of steel cracking in the later stage, our steel materials are heat treated by the original steel manufacturer. Generally, the hardness of heat treatment is 48-52HRC. According to the special requirements of customers, it can be hardened to 54-56HRC. The harder the steel, the greater the risk of cracking.

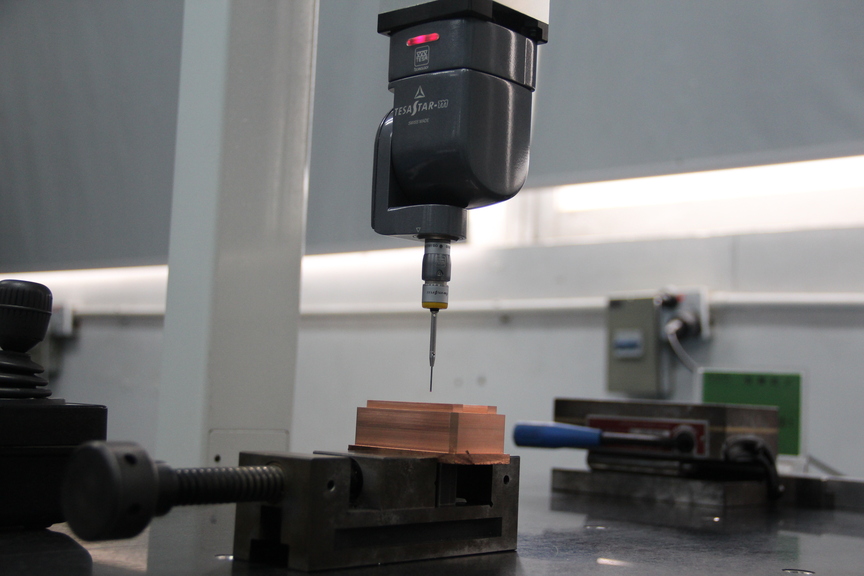

Before and after each process, there will be QC inspection to ensure the size of the parts.

If the plastic contains special minerals that are corrosive or abrasive to the steel, we will do coating treatment on the steel, such as chromium nitride, galvanizing, nitriding, etc.

After the steel material is hardened, the steel material should be finished. Finishing machining is divided into grinding machine, wire cutting, CNC, EDM

After the steel material is hardened, the steel material should be finished. Finishing machining is divided into grinding machines, wire cutting, CNC, and EDM grinding machines include ordinary grinding machines to grind small workpieces and large water mills to grind the die kernels before and after. The processing accuracy of the grinding machines reaches +/-0.002 mm.

Wire cutting is divided into medium wire cutting and slow wire cutting. Different processes can be selected according to tolerance requirements. Normal Wirecut and Precision Wirecut wire cutting are used to cut top pinholes, insert holes, inclined top holes, etc.

Wire cutting is divided into medium wire cutting and slow wire cutting. Different processes can be selected according to tolerance requirements. Normal Wirecut and Precision Wirecut wire cutting are used to cut top pinholes, insert holes, inclined top holes, etc.

EDM is used to process areas on the mold meat that cannot be processed by CNC, and to make some EDM textures, etc.

Polishing is to increase the smoothness of the mold, so that the surface of the product produced by the mold is smooth, beautiful and beautiful. The other is to make the mold easily demolded, so that the plastic does not stick to the mold and cannot be removed.

Polishing is a very important process in the process of mold making. Generally, mold polishing first uses coarse oilstone to grind the surface of the machined mold cavity, grind the knife marks of the machine and cutting tool, and then uses fine oilstone to grind the traces of coarse oilstone polishing, and then uses fine sandpaper to grind the surface of the fine oilstone polishing, and finally uses polishing paste or grinding paste to grind the surface of the mold cavity, so as to achieve a bright mirror effect.

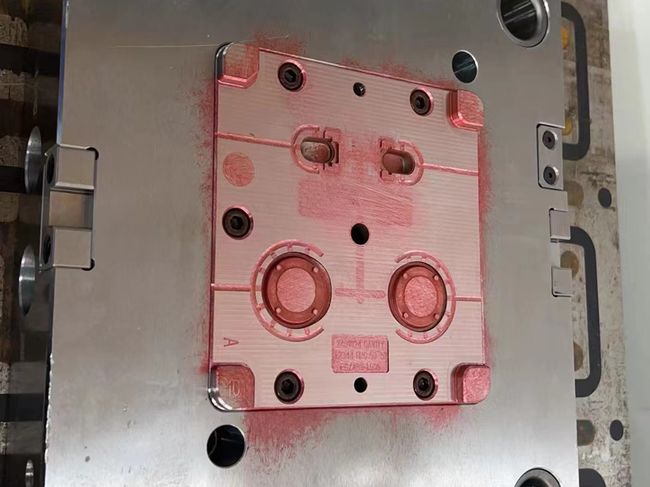

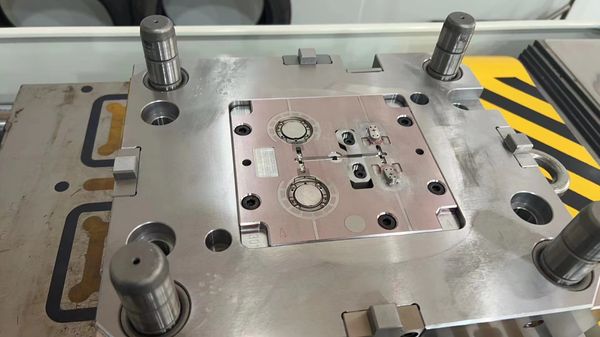

Fit Machine for Mold Assembly,Let the faces of the mold coincide well with each other. If it is not ideal, it will be corrected by a fitter.

After assembling the mold, it will be put in the injection mold for doing trail shoot.